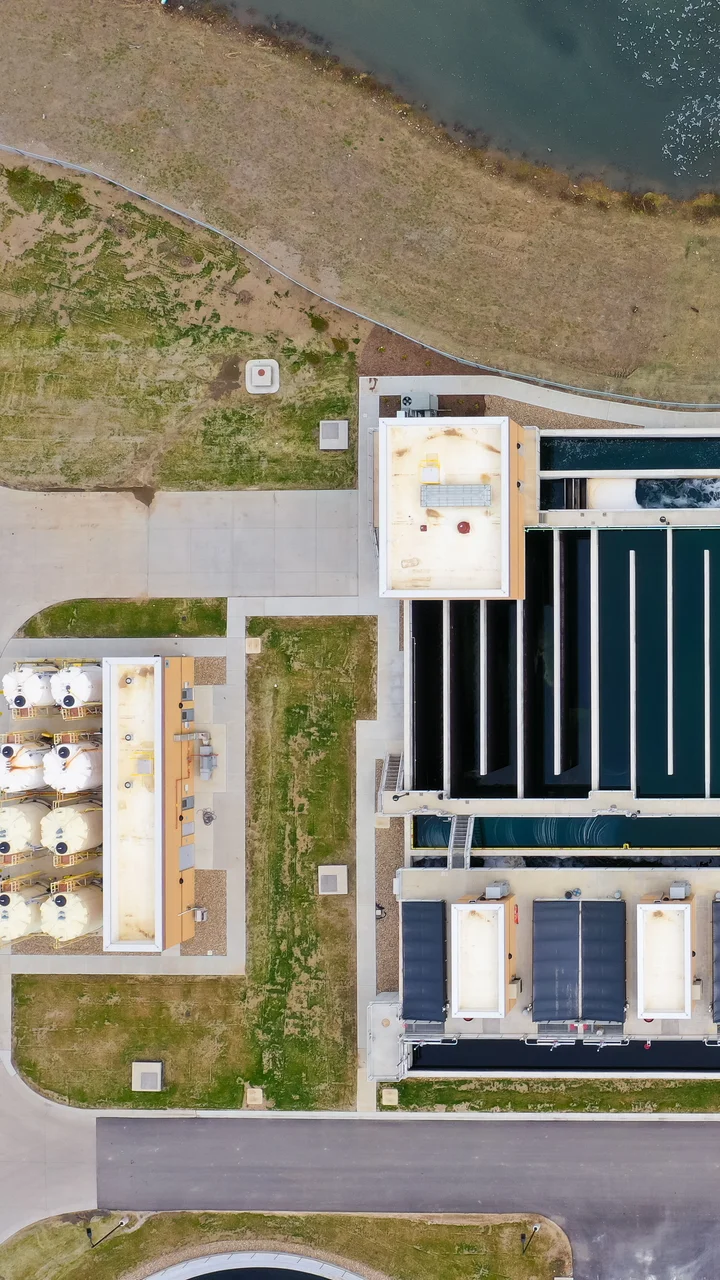

Tomahawk Creek Wastewater Treatment Facility Upgrade

- Project Name

- Tomahawk Creek Wastewater Treatment Facility Upgrade

- Location

- Leawood, KS

- Client

- Johnson County Wastewater

Faced with the need for a more efficient, sustainable treatment plant that could adequately serve its growing population and meet new discharge regulations, Johnson County Wastewater (JCW), located in the southwest portion of the Kansas City metro area, turned to Black & Veatch to help expand its Tomahawk Creek Wastewater Treatment facility, resulting in upgrades that saved the county approximately $16 million a year.

Identifying the Need

The county had known for years that the facility’s capacity was maxed out; that the more than 50-year-old infrastructure was not prepared to live up to the efficiency standards the county envisioned for its future, and that it would fail to accommodate increasingly stringent regulations. On top of that, JCW had spent decades sending 60 percent of the Tomahawk service area wastewater to a neighboring utility for treatment due to lack of capacity. The cost for that treatment had been steadily rising and represented a significant current and future economic risk to JCW rate payers.

The original Tomahawk Creek Wastewater Treatment Facility, built in 1955, had been dutifully treating 7 million gallons per day (MGD) of wastewater flows for decades. But in collecting wastewater from both the Indian Creek and Tomahawk Creek watersheds, which have flows ranging from 15 MGD on average to above 150 MGD during wet weather, the facility had more than maxed its capacity.

The county opted to send approximately 60 percent of its incoming flow to Kansas City, Missouri, treating only the remaining 40 percent at the Tomahawk facility. Though this strategy initially helped to keep capital costs at bay, it led to an increase in overall annual operational costs of the wastewater treatment plant, as the cost was two to three times higher than if the water had been treated in Johnson County.

In addition, the Environmental Protection Agency and the Kansas Department of Health and Environment had made changes requiring stricter discharge limits for ammonia, nitrogen and phosphorus. While nutrients such as phosphorus are vital for lifeforms, too much reduces water quality and can cause harm to aquatic life. To operate under the changing regulations, the facility required significant upgrades, especially as many of the plant’s aging assets were beyond their expected life.

Between the lack of adequate treatment capacity, increasing costs and the inability to accommodate changing regulations, it was clear the Tomahawk Creek Wastewater Treatment Facility was unsustainable for JCW both economically and environmentally.

After a third-party consultation, it was determined that expanding and upgrading the facility would provide the most cost-effective, long-term solution for rate payers. Expansion would enable JCW to treat all wastewater flows within its own facilities. Upgrades would leverage the latest, proven nutrient removal technologies to enhance water quality in Indian Creek and for downstream communities and allow the utility to help preserve the high quality of life enjoyed by county residents.

To accomplish these enhancements, JCW enlisted a team featuring Black & Veatch for engineering and construction inspection services.

Creating a Solution

As the prime consultant on this project, Black & Veatch teamed with HDR to provide engineering services. McCarthy Building Companies, Inc. was selected as the Construction Manager at Risk to expand the facility from 7 MGD to 19 MGD with up to 196 MGD of wet-weather treatment capacity — the largest project that the county has ever undertaken.

To accomplish this feat, Black & Veatch deployed the newest proven technologies across the operation. Facility improvements included new influent pumping and coarse screening, five-stage biological nutrient removal (BNR) treatment, intermediate pumping, disinfection, tertiary filtration, solids processing and more.

The new facility can treat up to 57 MGD using traditional treatment processes. When wet-weather conditions strike, cloth-disk filters can be used treat the additional flow. This auxiliary wet weather treatment facility is now the largest facility in the world to use disc-filter technology, with eight disk filters totaling a capacity of 115 MGD . Combined with the traditional process, the facility can accommodate flows up to 172 MGD.

Looking Forward

For years to come, the upgrades will help to protect the surrounding environment and improve water quality in Indian Creek and downstream communities, all while providing a lasting efficiency for county residents.

“What we’re doing here is we’re recycling water. We’re taking the wastewater a community produces, treating it and returning it back to the stream,” said Derek Cambridge, Project Director with Black & Veatch. “We [also] focus heavily on power consumption and trying to reduce the amount of power that’s required to treat wastewater. There’s a lot of energy that comes in with wastewater that we are able to harness and utilize in the treatment process."

This may be the biggest project JCW has ever taken on, but to many of the county’s residents, the work done at the Tomahawk Creek Wastewater Treatment facility will remain invisible. Although the residents of Johnson County likely think little about the behind-the-scenes operations that handle and treat the wastewater they flush away from their homes, they will feel the invaluable benefits to their surrounding environment — and a lesser impact on the rates they pay — for decades to come.

As of Spring 2022, the new Tomahawk Creek Wastewater Treatment Facility is providing wastewater treatment capacity to JCW without any need for additional treatment capacity from neighboring utilities, improvements that are estimated to save rate payers $785 million over the next 35 years.

Contact Us

Looking for a partner in innovation?

Let's Talk