Accelerating modularized LNG solutions

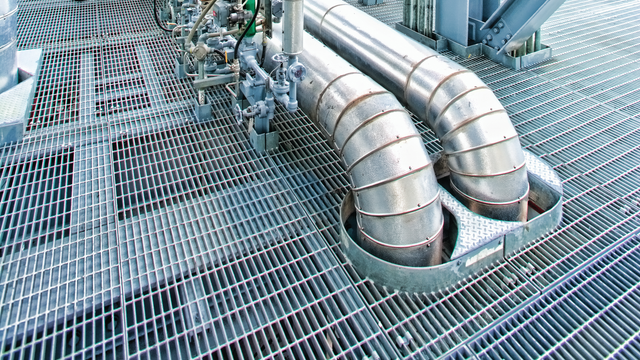

Beyond large baseload export facilities, liquefied natural gas (LNG) increasingly is relied upon to provide lower-carbon fuel directly to homes, industry and vehicles in many countries. Over the past several decades, we’ve been at the forefront of helping clients innovatively meet the demand.

As an industry pioneer with more than a half century of LNG expertise, we played a leading role in the dawning of many of the world’s first LNG facilities. We developed the PRICO® single-mixed refrigerant process for LNG, using a cost-effective design covering a range of LNG plant capacities that have been applied in 35 facilities around the globe.

Now as demand for lower-carbon energy sources accelerates around the world, the need for LNG infrastructure to propel the energy transition intensifies.

That’s where Black & Veatch comes in.

Small-Scale Liquefied Natural Gas

Small-scale liquefied natural gas (LNG) solutions are a “sweet spot” for fast-to-market results, with remote installation capabilities and truckable modules and skids. We deliver small-scale LNG solutions through:

Extensive PRICO® experience in the 10 to 40 MMSCFD range

Modularly designed and constructed projects with truck-transportable skids or prefabricated piping sections containing high concentrations of valving and instrumentation

Competitively priced projects due to standardized components and relationships with critical suppliers

Comprehensive industries across the gas value chain

Our global leadership stems from decades of proven performance on more than 3,000 assignments in more than 40 countries. We provide services from consulting, design and full engineering, procurement and construction (EPC), along with deep expertise in startups of LNG import and export facilities, FLNG, gas processing and NGL fractionation, gasification and ammonia/fertilizers.

The First LNG Terminal on North America's Pacific Coast is Delivering Natural Gas to Customers in Mexico and the United States

Ennore LNG terminal: Black & Veatch completes design-to-commissioning of LNG regasification terminal for Indian Oil LNG

Black & Veatch Provides Technical Expertise for a Low-Emissions Natural Gas Plant in Thailand

Contact Us

Looking for a partner in innovation?

Let's Talk