Providing a Vital Power Source

- Project Name

- Oregon Clean Energy Center

- Location

- Oregon, Ohio

- Client

- Oregon Clean Energy Center, LLC

Advanced Combined Cycle Facility Delivers Value to Community, Environment, Investors

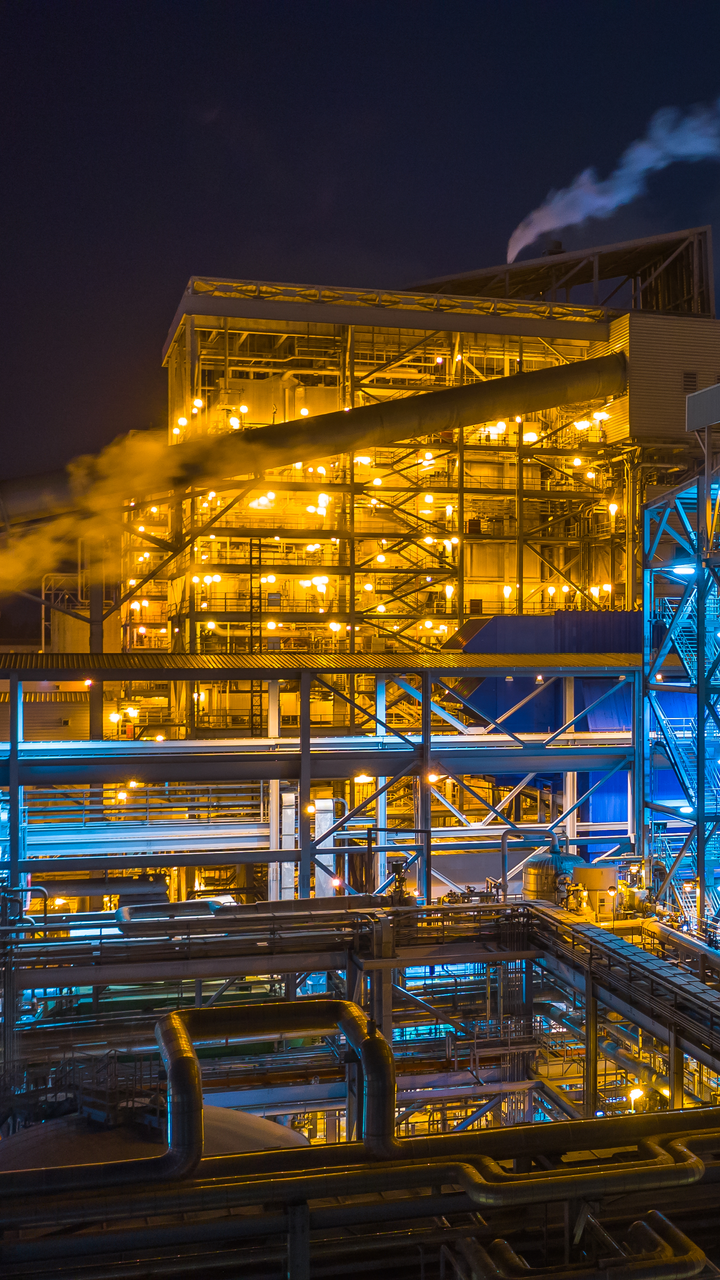

Near the shore of Lake Erie, in Oregon, Ohio, an 869-megawatt (MW) combined cycle power plant, known as the Oregon Clean Energy Center, is now providing critical baseload power to the PJM regional transmission organization and delivering value to virtually all stakeholders.

“This is an extremely efficient plant in terms of required manpower, thermodynamics and emissions,” said Peter Rigney, General Manager of the Oregon Clean Energy Center. “There is an astronomical amount of automation on this facility. During normal operations, it can run with just two people.”

Located in a former soybean field, the plant replaced aging coal plants in the region that had recently been shut down. The new plant provides a vital power source to an industrial region dominated by large users, including a major refinery and several automobile factories. Toledo, with a population of nearly 300,000, is also nearby.

“The Oregon Clean Energy Center brings lower price energy with fewer emissions to the area,” said Mike Beazley, Oregon City Administrator. “During construction, I liked seeing local people going to work. Today we have a plant that is lowering the price of energy and providing clean energy for everyone in the region. The clean energy side is the secondary payoff that’s hard to quantify, but it works for the region, the community and for our Great Lake.”

A "Fully Wrapped Project"

The 2x1 natural gas combined cycle power plant was built on a greenfield site that was developed by North American Project Development, LLC and is owned by Ares Capital and I-Squared Capital. The facility includes two Siemens H-class combustion turbines, a Siemens SST6-5000 steam turbine and NEM heat recovery steam generators (HRSGs).

Black & Veatch was the engineering, procurement and construction (EPC) contractor for the project, which included developing the Environmental Control Program for construction activities, procurement of all equipment and materials, construction planning and permitting and self-performing construction through BVCI, a wholly owned subsidiary of Black & Veatch.

Black & Veatch leveraged its extensive engineering and procurement capabilities, direct hire union construction experience, and startup capabilities to bring together a team capable of overcoming significant challenges including a small site footprint, winter construction, and equipment fabrication issues to complete the project on time and within budget.

"This was a fully wrapped project, which made my life easier. I had one door to knock on. Black & Veatch took care of all the interface with Siemens and the numerous subcontractors. It was really an excellent project."

Peter Rigney, General Manager of the Oregon Clean Energy Center

Detailed Design

Before construction began, Black & Veatch used 3D modeling technology that allowed the client to walk through the plant before it was built and provide input from an operations and maintenance standpoint. While this type of software has been around for years, today's versions are so detailed that the client was able review design details such as the location of doors, walkways, pipe routing, valves and handwheel positions and instrument locations to help create the most efficient space possible allowing for the client to provide input into the design decision process. This review helped limit the amount of expensive changes that typically occur in projects of this scope.

"At the end of the day, we only had 10 change orders on this entire plant. I think that speaks to the design team at Black & Veatch, or the review process we went through on a monthly basis during the early phases of the project."

Peter Rigney, General Manager of the Oregon Clean Energy Center

Positive Community Impact

The Oregon Clean Energy Center has an estimated, long-term economic impact of $14 billion dollars for the region. The project employed more than 500 skilled workers at construction peak.

“The Oregon Clean Energy Center put people to work, it brings in tax revenue for the community, which allows us to pay for services,” said Beazley.

Beazley continued, “We want to make sure we can peacefully coexist with heavy industry. We want our residents to be able to enjoy a quality of life here. At the same time we want to attract a sort of heavy industry that puts people to work and drives our economy. A successful project like this demonstrates to our residents and to the rest of the community that we can do this, let’s do it again.”

Contact Us

Looking for a partner in innovation?

Let's Talk