Removing phosphorus, among other nutrients, from treated wastewater effluent is essential to protecting water quality in receiving bodies. Removal via biological treatment has been widely adopted since it was first found to be effective in the 1970s for its efficiency and its economic and environmental benefits over chemical treatment. As the treatment approach evolved, one of the disadvantages of enhanced biological phosphorus removal (EBPR) was its instability under certain conditions.

The Water Research Foundation (WRF) commissioned a comprehensive investigation of a particular EBPR configuration – sidestream enhanced biological phosphorus removal (S2EPBR) – that prior research had shown to be effective in addressing the issue. The investigation focused specifically on biomass fermentation and how it promotes stability in the S2EBPR process. Doing so, the project developed a first-ever standard approach to implementing S2EBPR, including design, operational, and modeling considerations, for optimized phosphorus removal.

The WRF investigation was conducted at a national level with Leon Downing of Black & Veatch as the Principal Investigator leading a team of renowned EBPR pioneers and researchers, including April Gu of Cornell University and Dr. James Barnard of Black & Veatch, with support from engineering consulting firms, water utilities and research institutions serving as case-study partners and technical reviewers.

Drivers and Approach

After EBPR was first observed in the 1970s, extensive experimentation, testing, and modeling advanced understanding of its processes. Numerous conventional configurations were developed including S2EBPR. The appeal of S2EBPR was research that showed biomass fermentation increased the process’s stability. Absent a standard design approach, and with regulatory limits on phosphorus in wastewater effluent becoming more commonplace and stringent, WRF launched an investigation into S2EBPR’s underlying mechanisms.

Led by Black & Veatch’s Innovation Platform team, which completes applied research to advance pioneering technologies and concepts for clients, the research focused particularly on practical approaches to implementing fermentative processes in EBPR systems. The main driver was to develop a systematic design approach complemented by operational tools and modeling considerations. A secondary advantage of S2EBPR is the role of fermentation in decarbonization of biological nutrient removal.

From a process engineering perspective, the team studied 19 facilities where S2EBPR concepts were implemented at full scale either as a demonstration project or as part of a permanent design. Performance data, testing information, and modeling were used to address key questions including the rate of biomass fermentation in the activated sludge process, site-specific parameters impacting the fermentation rates, and the amount of carbon needed relative to phosphorus. A meta-data analysis approach was used to understand performance drivers and operational parameters. Additionally, 17 separate group discussions were held to share data and consolidate opinions.

Key Findings

The project provided a process design framework to include biomass fermentation in sidestream return-activated-sludge (RAS) fermentation zones based on a carbon balance approach. The framework enables users to achieve effluent phosphorus concentrations as low as 0.2 mg/L and minimize the amount of supplemental chemicals needed. Key findings of the framework included the following.

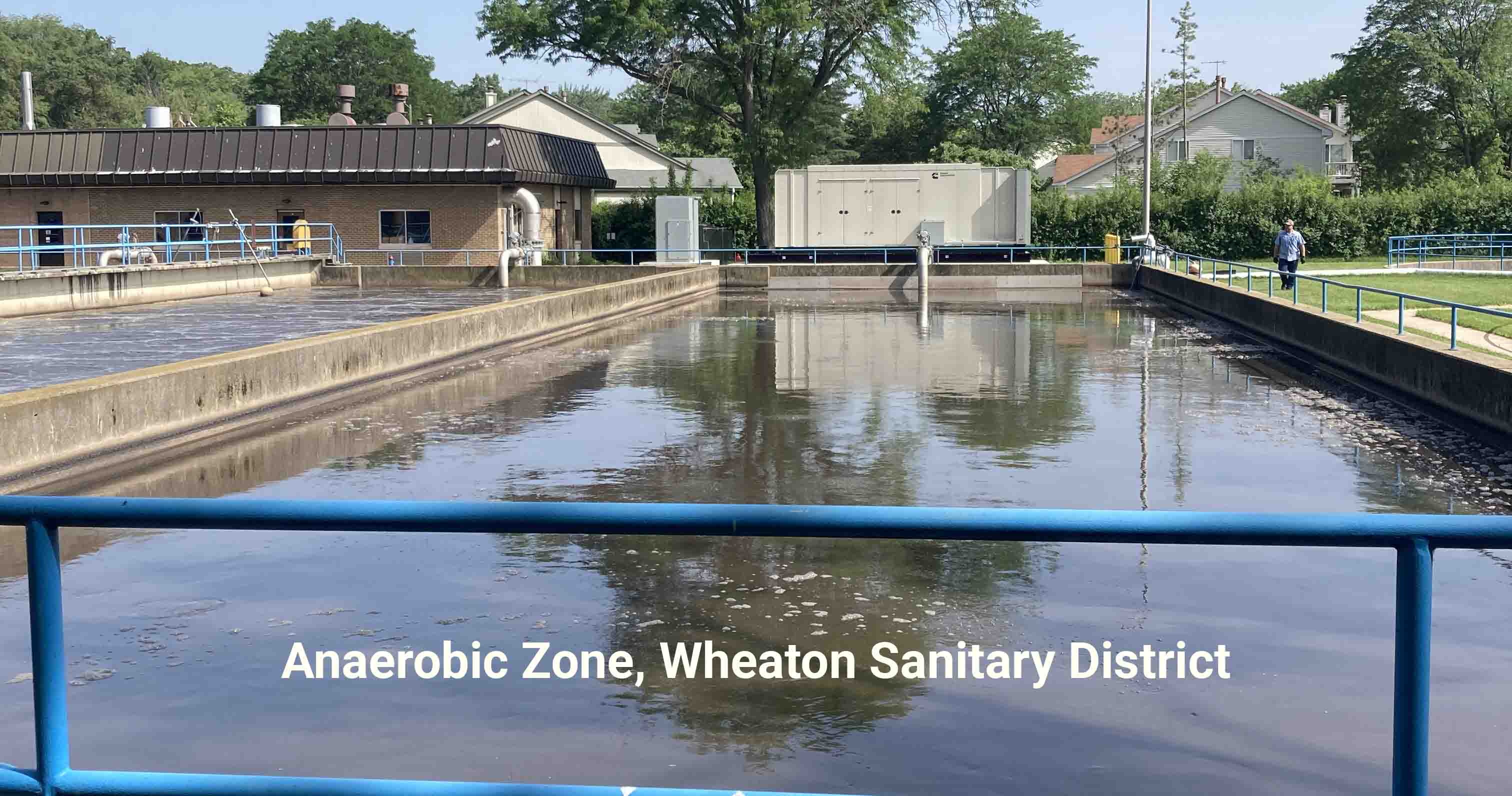

A design approach that focused on a carbon balance around an anaerobic zone, identification of mixing impacts, and recommendations for sizing.

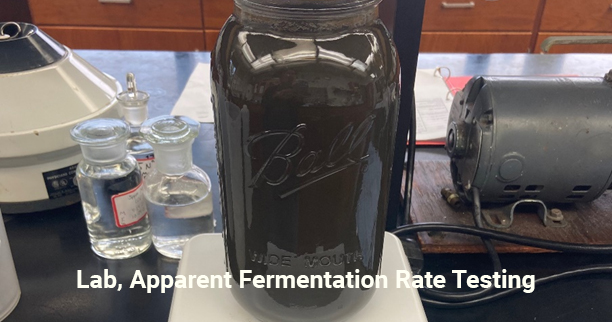

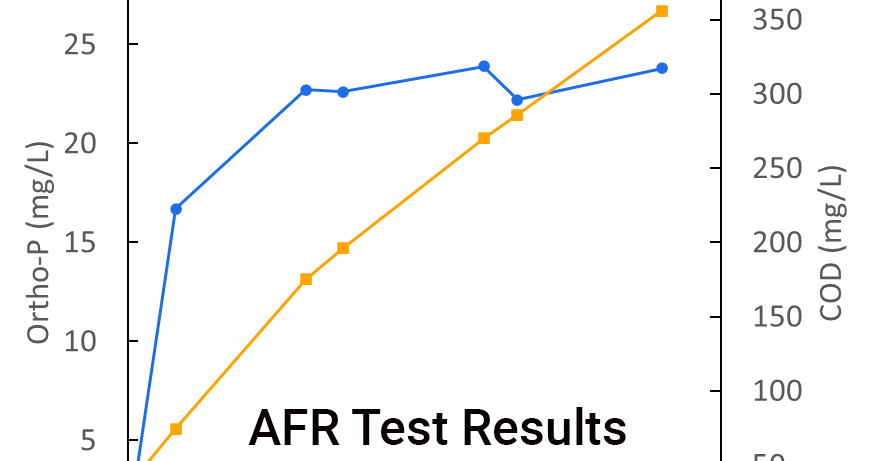

Operational guidance related to cyclic mixer operation, fermentation rates, and the compilation of approaches for establishing the apparent fermentation rate (AFR) to assess fermentability of biomass streams.

Process modeling guidance to better predict the performance of fermentation and EBPR processes.